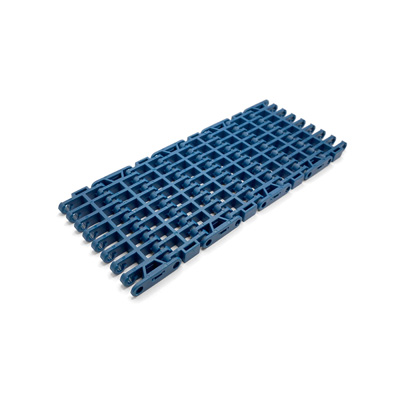

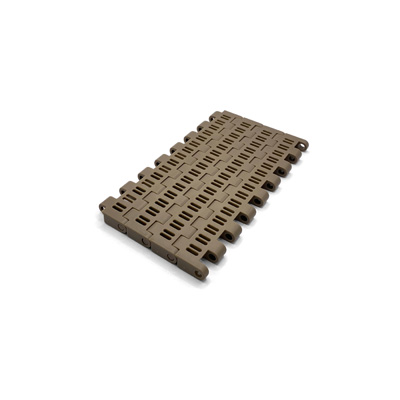

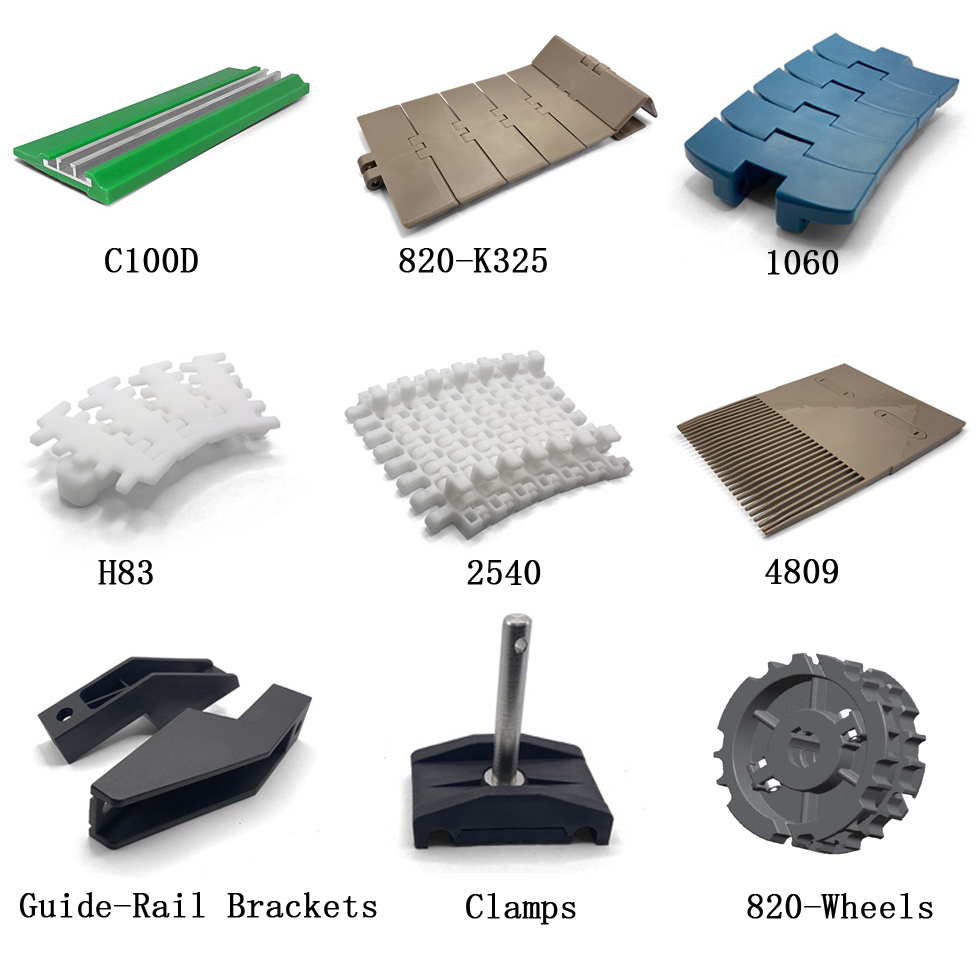

Jetway Conveyor Belt Flush Grid 1000 Materials Food Transport Belts Transmission Chains Belt Pitch 25.4mm

Product Display

Quick Details

1.Luohe Global modular conveyor belt has more than 10 times service life,long life time and reducing replacement cost than traditional conveyor belt.

Applications

FAQ

1. Q:Are you a factory outlets or trading company?

A:We are a factory outlets.

2. Q:If small order is acceptable? Yes,trial order is welcome!

A:Yes,trial order is welcome!

3. Q:Could you offer us samples?

A:Yes, generally, free sample for 1~2pcs, and the freigt you need to bear.

4. Q:What’s your shipment terms?

A:Generally, if samples, by air or by express; If bigger order by sea.

5. Q:Could you put our logo on the packing?

A:Yes, it is easy to print your logo on the packing.

6. Q:What’s your package?

A:In standard export cartons, but could be designed as your request.

7. Q:What’s your main port of lading?

A:FoShan/GuangZhou/ShenZhen/ShangHai/NingBo.

Packaging and Shipping

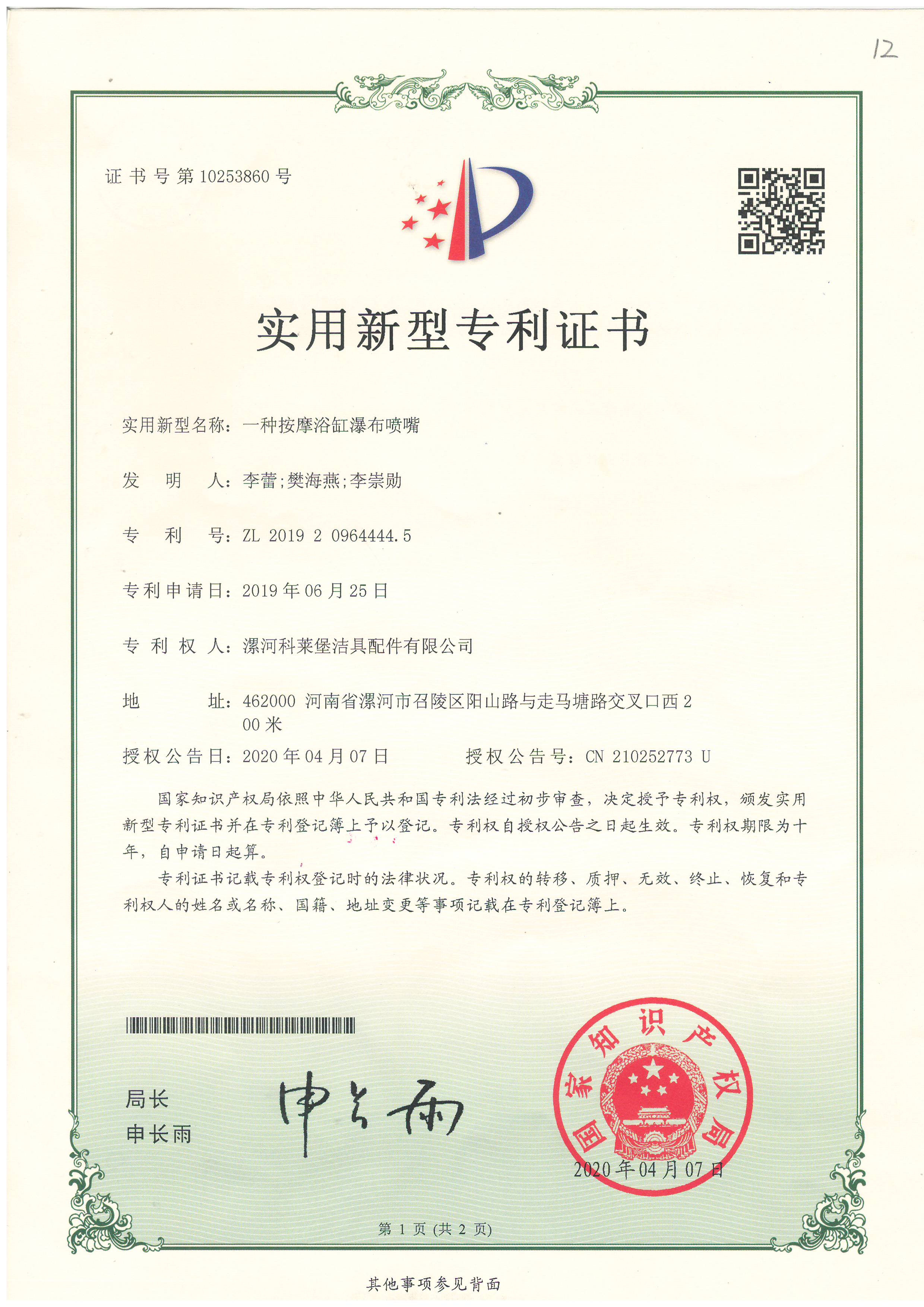

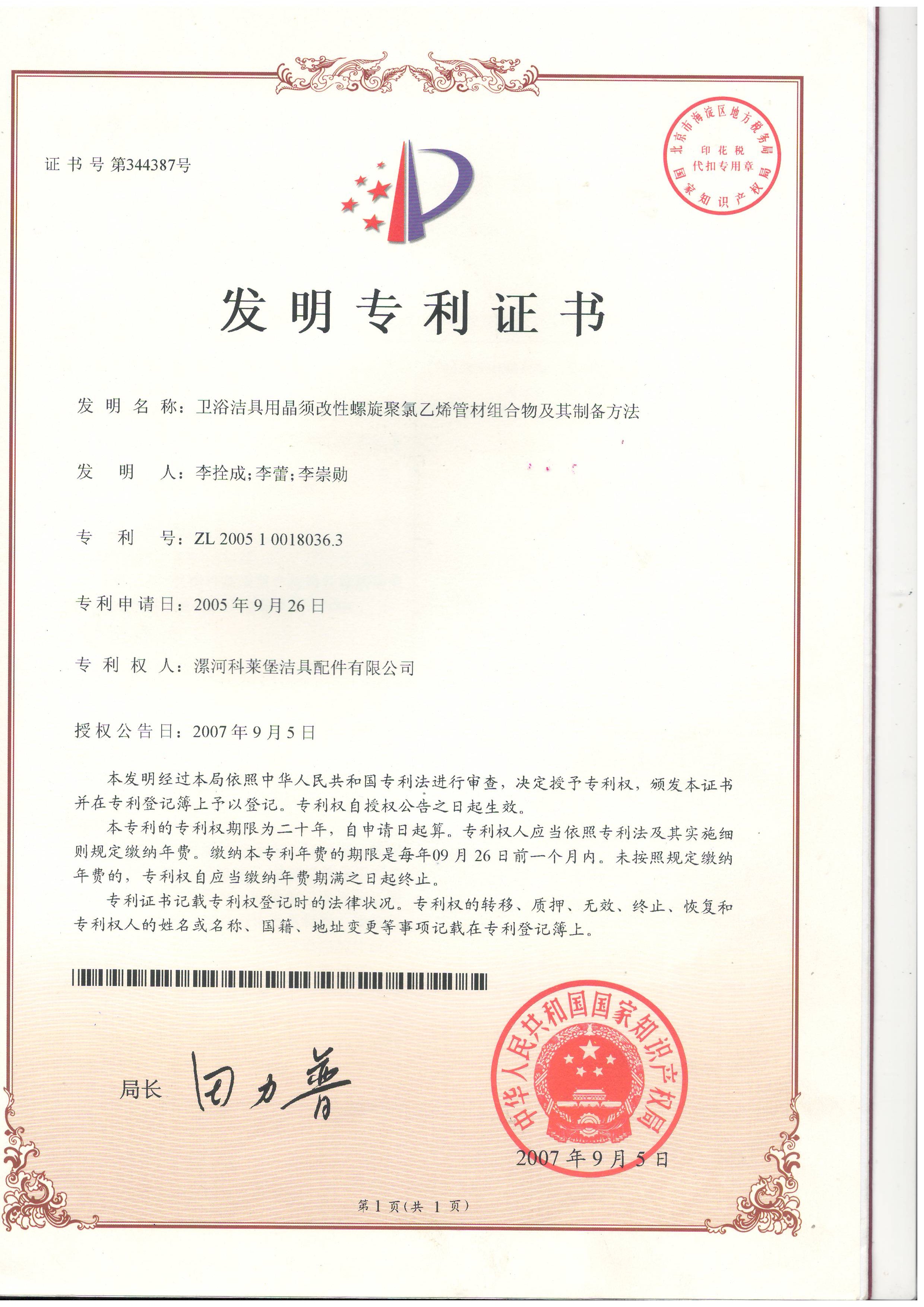

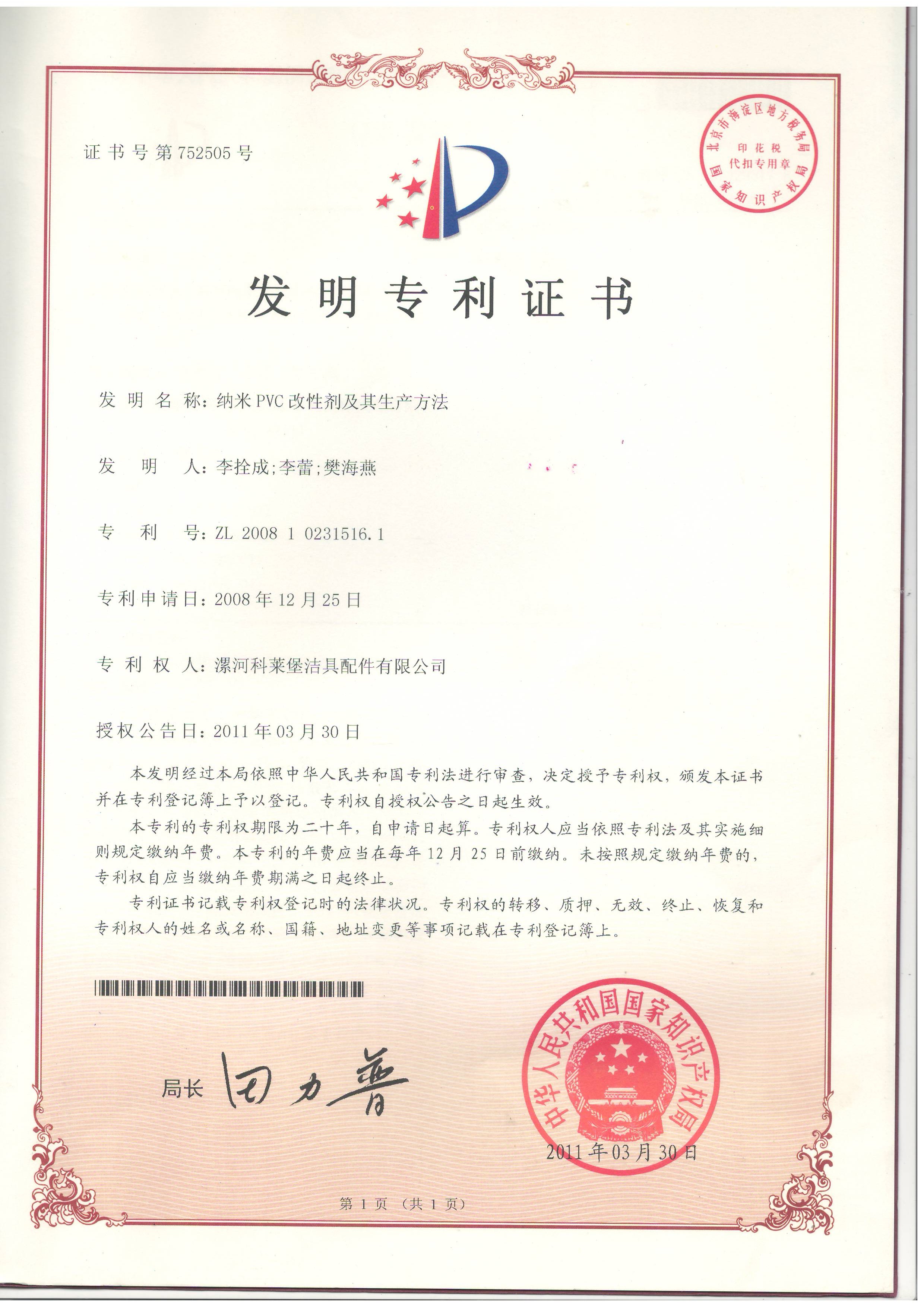

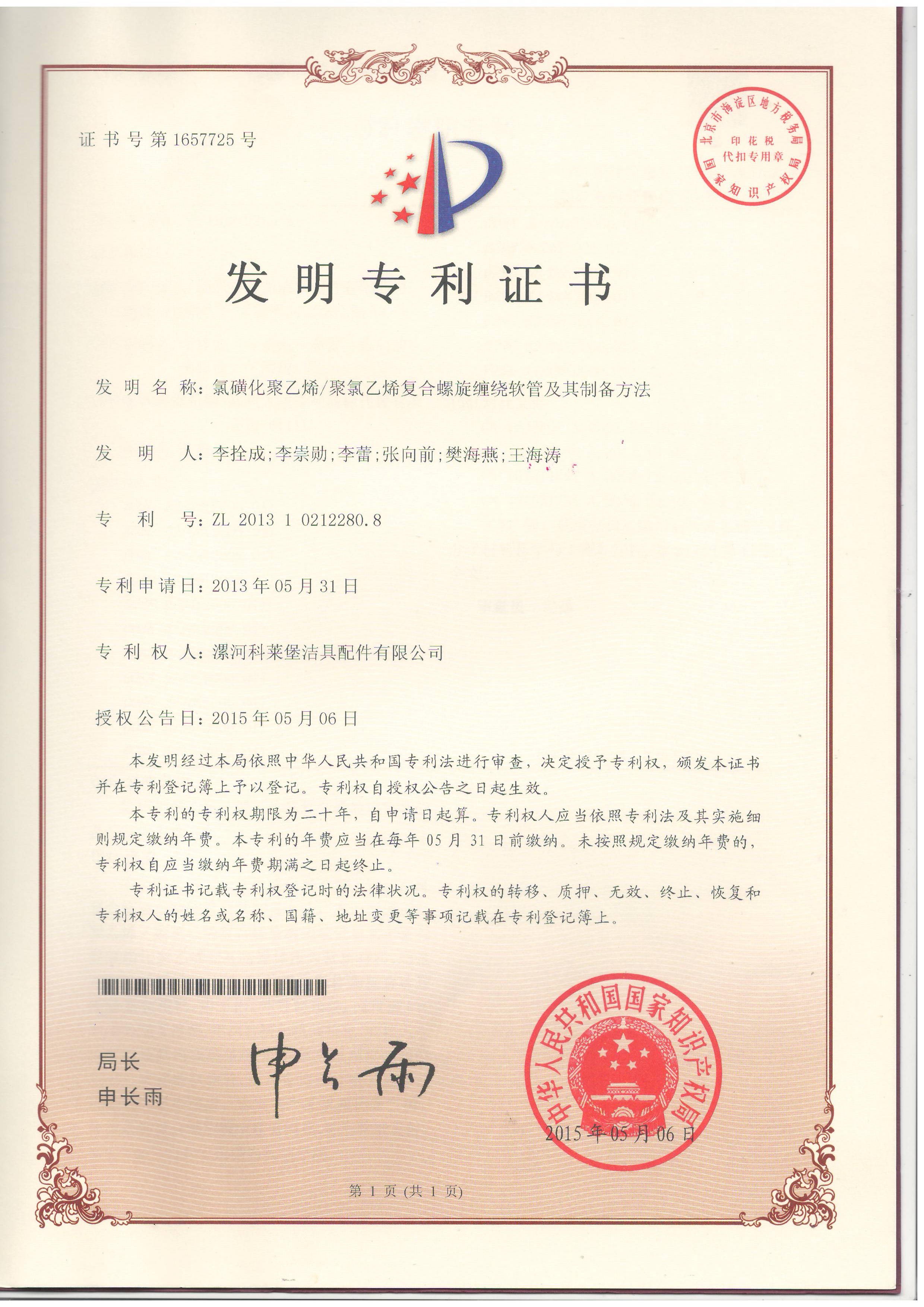

Certificates

1.png)

3-213x300.png)

1.png)

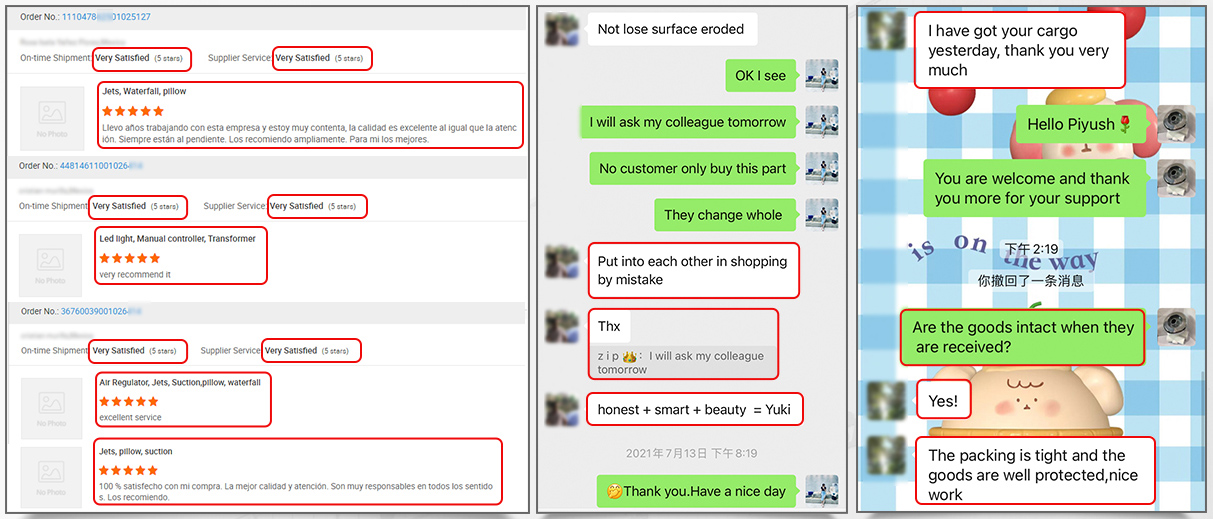

Customer Feedback

Photos of Exhibition Customers Collection

Welcome to Visit Our Factory

News

Modular plastic belts

Luohe Global modular plastic belts range covers over 150 different styles in a wide range of materials for most demanding applications. Contact us today.

modular plastic belts offer a significant advantage over the conventional conveyor belts. It is lightweight and therefore requires only light support structures, such as low-power motor equipment, which reduces the energy cost. The product design also enables easy replacement of even the tiny components. The identical styles prevent dirt from accumulating below the belt. Both plastic and metal conveying belts are a great choice for the food processing business.

Luohe Global Jetway is the leading manufacturer of modular plastic belts for various Industries. The conveyor belts are designed and manufactured with FDA approved materials. The modular plastic belts from Luohe Global Jetway enhance and support to achieve the desired conveying output capacity within less operational time. The modular plastic belt conveyor is designed to perform seamlessly and is suitable for industries that demand mass flow operation of products. The plastic conveyor belts are lightweight and designed Bottles, cans , crates, kegs and cartons.

modular plastic belts are robust in construction, easy to maintain and hygienic in operation.

Plastic modular plastic belt is designed for easy assembling and disassembling after cleaning and requires lesser time to cleaning and fitments on the conveyor compared to endless belts Luohe Global Jetway manufactures belts that deliver safe product conveying, stronger and smooth belt parts for improvised productivity. Application specific configurations of conveyor belts can also be recommended to drain water from the product or cool, while conveying the same.

Luohe Global Jetway offers Modular plastic conveyor belts for a wide range of temperatures, in applications. Our belts run in cold storage of dairy, seafood and meat products. Our products can work in Individually Quick Frozen(IQF) and blancher applications, covering a wide temperature range of -40 degC to 115 degC.

The modular plastic belt is highly reliable and is suitable for critical applications with increased performance and transfer capability. We manufacture modular plastic belts with raw materials of global standards; and expertise to ensure consistent product quality. This helps the customers to have smoother product transfers, less conveyor down-time, easy maintenance and easy cleaning of belts.

Why Luohe Global Jetway?

Positive drive and tracking

modular plastic belts do not need any pre-tensioning and are not affected by mistracking issues often caused by a poor conveyor design or heavy contamination. The positive drive given from sprockets avoids any possible belt slippage and guarantees smooth operations resulting in much less maintenance and downtime.

Resistance to extreme conditions

modular plastic belts work safely and reliably in a wide range of conditions and temperature ranging from -70°C to +240°C. Luohe Global Jetway product range has a solution for wide temperature variations, humidity, aggressive chemical agents, cutting operations, product impact, high speed and abrasive environments.

Quick repair and maintenance

It is unusual for a plastic modular belt to require maintenance or repair, but, should it become necessary, the belt is easily opened using simple tools such as a screwdriver. It can be repaired and re-closed in a short period of time without the need to replace the full belt. Downtime is reduced to a minimum and, as modular plastic belts do not need lubrication, no additional maintenance is required.

Suitable for aggressive chemical agents

In food applications, belt sanitation is a key element of the customers’ safety requirements. To ensure high safety standards, all equipment and belts have to be deep cleaned using aggressive detergents before being rinsed clear.

Luohe Global Jetway engineered plastic materials offer a top-level resistance to the cleaning agents used in the food industry.

Longer lifetime

Under standard conditions, modular plastic belts usually have a very long lifetime, lasting for years without a change in performance and little or no maintenance.

High strength

Compared with other belting solutions, modular plastic belts offer a very high strength, which can cope with all of the most demanding applications of the industry. At the same time, they are also suitable for accumulation and diverting applications which affect the behavior and lifetime of other belting solutions.

Wide range of surfaces

Luohe Global Jetway modular plastic belts offer a wide range of different surfaces to deliver the specific properties required. From flush grid to roller top there is a surface that will match the requirements of your belting application.

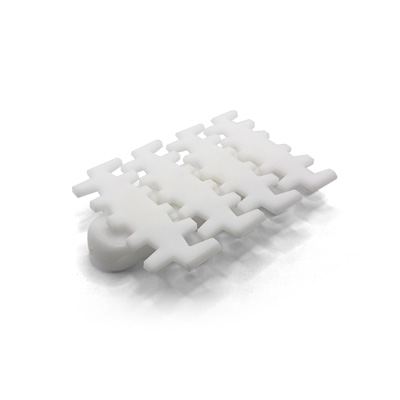

Innovative design for even more efficient cleaning

The ultimate solution to significantly reduce the risk of cross-contamination and increase the efficiency of cleaning of modular plastic belts is to increase the ratio of flat, homogeneous surfaces and minimize the number of hinges and rods. The unique, patent-pending design of Super Jetway belt range provides exactly this advantage.

Minimized use of hinges and rods - reduced by up to 80% compared to the traditional modular belt. This results in a reduction of the total exposed surface of the belt by 33%.

Pockets and corners placed at the lateral sides of the belt increase the flat surface with minimal cavities on the running side of the belt.

Mold to width belt configuration means that there are no fractures in-between modules on the width of the belt.

Dynamic open hinge creates a robust structure to drive the belts with only two sprockets.

The lateral opening of the hinges allows the water flow to reach hinges and rods with an easy flush away.

Optimized for cleanability

Jetway belts are characterized by superior rod exposure, a significant reduction of hinges, and wide made to width modules, which reduces the number of interruptions in the belt.

The result is an 85% rod exposure, for superior belt cleanability.

The Jetway package includes a 2” flat top module and a sprocket, both with a unique, patented hygienic design.

Dynamic open hinge design with extra-wide, open links and oblong holes provides improves the release of debris and cleaning efficiency. The sprockets come equipped with a slot between teeth pairs, which minimizes contact surface with the belt's reverse side without compromising the engagement.

Jetway provides unique in the market, 100% hinge exposure over the entire belt width.